DFA – Deep Field Analysis

Patented sensor technology for fast quality inspection of metallic parts

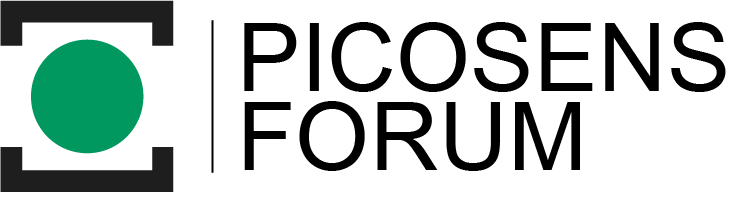

Hows does DFA work?

- Excitation with a ramp-shaped electromagnetic signal

- Formation of eddy currents in the sample

- The sensor measures the voltage-time curve of the emitted field – the inductive fingerprint

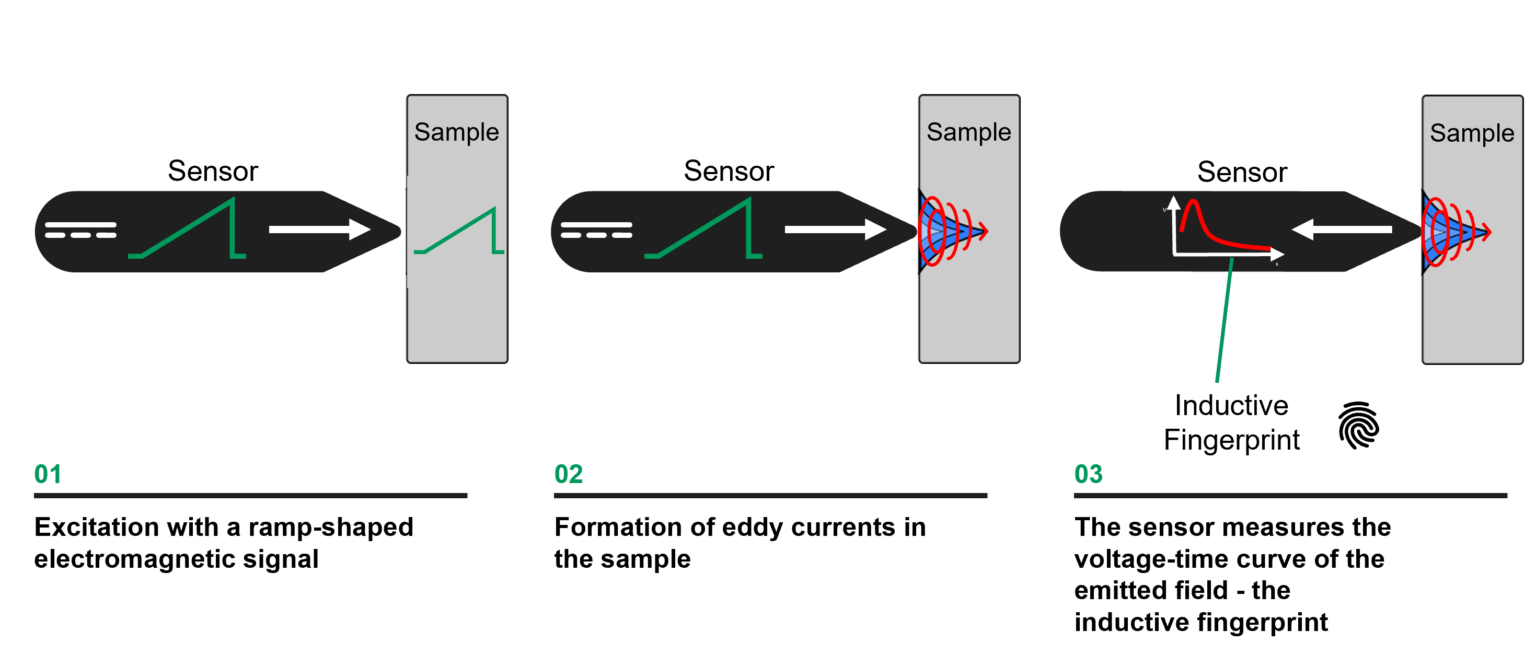

The sum of the material properties is measured, while disturbing factors are largely compensated.

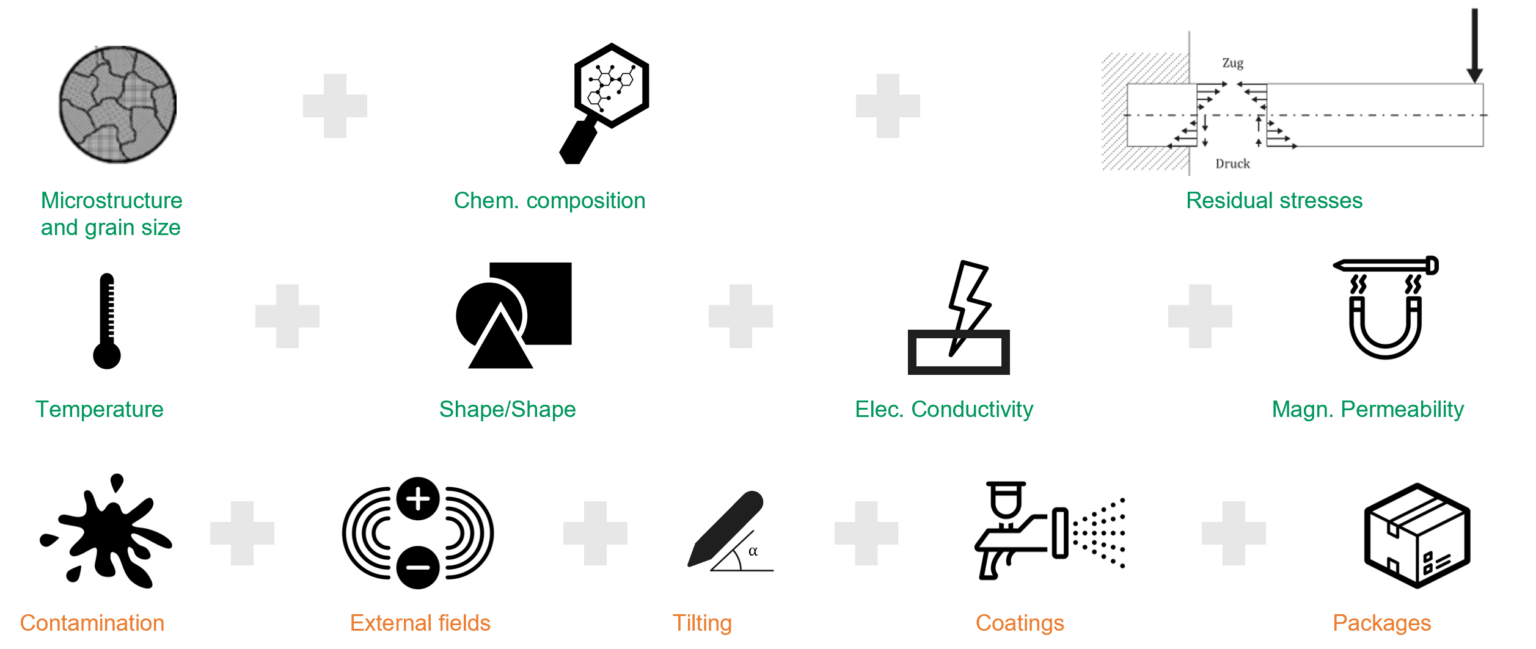

What makes DFA special?

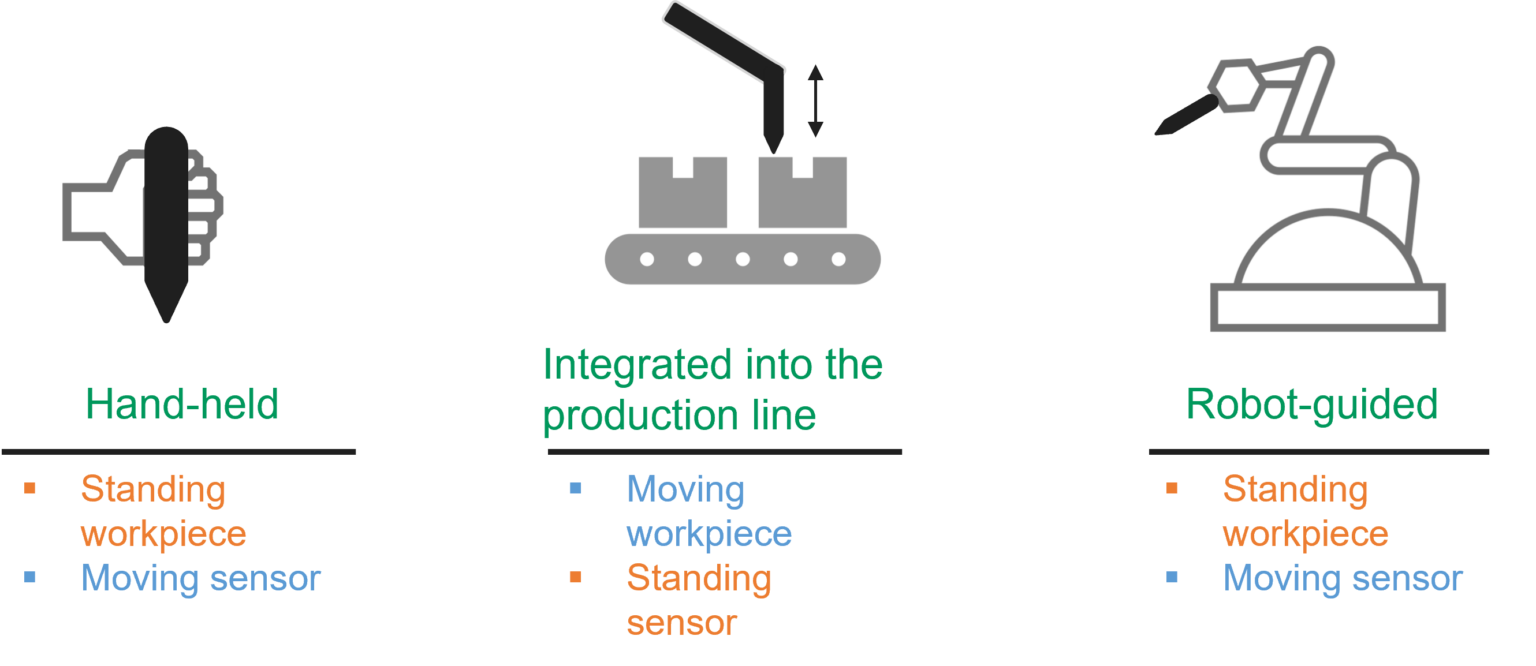

Application types

Sorting hardened gears

Application

Due to a system error, exactly 1 tooth was not induction hardened on a few parts. The fault was discovered when 90,000 gearboxes had already been delivered to the customer.

Solution

The handheld device enables fast, non-destructive and safe detection of the defective tooth

Added value

Testing possible at the customer. Avoidance of unnecessary component destruction in value of approx. 10 million EUR

100% IPC-NDT during heat treatment

Application

Monitoring of hardened and tempered steel beams. Time-consuming 100% of Brinell hardness.

Solution

Correlation of the DFA values with the Brinell measurement enables an 80% reduction in inspection time

Added Value

Personnel reduction by 50% with the handheld device. Future automation possible.

Simple testing of precious metal

Application

A large amount of gold coins to be tested for authenticity

Solution

Differences become visible through comparison with a reference coin

Added value

Testing by the customer possible with the help of a loaner device. The private sale of Krugerrand gold coins was made possible.

Hardness distribution for tools

Application

Case hardened parts are optimized. Tuning of the hardening tool.

Solution

Scanning of components provides the toolmaker with quick feedback

Added Value

Optimized component quality. Improvement of homogeneity leads to energy saving of 8%.

Sorting material mix-ups

Application

Contaminated bulk material cannot be processed automatically. Manual sorting is too expensive.

Solution

As an automated sensor, DFA detects the differences in the process Different products are monitored with the same sensor

Added value

Low-Cost Process safeguarding. Scrap avoidance

Recognizing tensions

Application

Coated films become wavy due to inhomogeneous stress conditions and elongation. Difficult web guiding and winding.

Solution

As an automated sensor, DFA also detects shape defects in metallic foils in the process. Multiple sensors monitor across the width and length.

Added Value

Significant increase in output due to improved process control.

Inhomogeneity during forging

Application

Defective spots in forgings lead to visual defects and a reduction in structural strength.

Solution

Reliable process monitoring detects structural defects even below the surface.

Added Value

Possibility of 100% control for safety-relevant components

Composite materials monitoring

Appication

In solder cladding, ensuring the correct layer structure has high priority. Mix-ups lead to high damages during further processing.

Solution

The DFA check also distinguishes several layers safely

Added Value

Increased security for the customer

Contact